Monitoring sugar levels in potatoes is an important process for growers as it can help minimize losses from effects that influence processed product color. In other words, when chips or fries are made, if the glucose level is too high, their color will be darker, which is undesirable. Let’s take a more detailed look at why this happens, how to reduce sugar content in potatoes, and how to monitor these levels.

A Dark Colored Fry or Chip

Sucrose is the major free sugar found in immature potatoes, and it’s the primary source of carbons and energy for starch synthesis and growth. As potatoes grow, some of the carbon from the sucrose is completely oxidized to CO2, H2O, and energy. Invertase is an enzyme produced by yeast that catalyzes the hydrolysis of sucrose, forming invert sugar.

If a protein inhibitor prevents the invertase from breaking down the sucrose during growth, the invertase reaction becomes active in storage, producing undesirable reducing sugars from the available sucrose pool. The result is high levels of sucrose present in the potatoes at harvest.

Why is this a bad thing? When raw potatoes are sliced and fried at high temperatures, excess reducing sugars react with the abundant free amino acids in the potato cell, forming brown to black pigmented chips.

Increased Levels of Reducing Sugars

So what causes increased levels of reducing sugars?

There are several factors that influence the sugar content of a potato, including the variety, growing season, vine kill, harvest and storage. Other factors can include storage duration and ventilation, as well as transport and handling.

Many researchers believe storage temperature is a major source of the problem. Several studies have been done showing that colder storage temperatures can lead to increased reducing sugars. Even a few degrees can make a big difference. Recommended storage temperatures can vary by potato variety and the desired end use.

Monitoring Sugar Levels

Glucose and fructose are the building blocks of sucrose, and our Potato Test Paper detects levels of glucose in the potato. This is one way to monitor sugar levels in potatoes. In general, glucose levels below 0.1% are acceptable for french fry processing quality. Glucose levels of 0.2% and below are ideal for quality dehydrated potato products, such as potato chips.

Glucose and fructose are the building blocks of sucrose, and our Potato Test Paper detects levels of glucose in the potato. This is one way to monitor sugar levels in potatoes. In general, glucose levels below 0.1% are acceptable for french fry processing quality. Glucose levels of 0.2% and below are ideal for quality dehydrated potato products, such as potato chips.

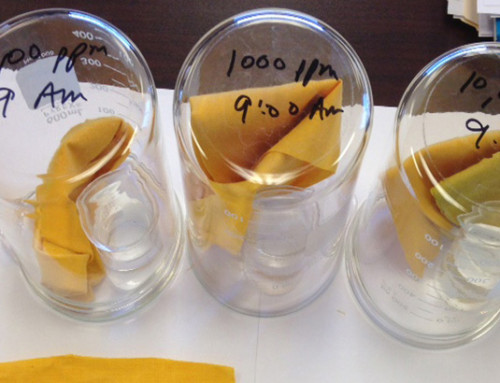

When sampling potatoes, it’s important to select from two sample sets, selecting a random 5 or 6 potatoes from each sample. Cut one potato in half lengthwise. Remove one potato test paper from the bag, and try not to handle the test strip with your hands except where you grasp it at the end.

Apply the strip flat to the length of the potato and press the two halves of the cut potato back together, so that all parts of the strip are moistened with potato juice. Immediately remove the strip from the potato, and then wait 1 minute before comparing to the color chart.

If the strip remains yellow, it indicates that no glucose sugar is present and the potato chips will fry a light color. If the strip turns green, compare it to the color chart. Any strip darker than the color block associated with 1/10% will likely fry to a dark color.

Wipe the knife blade clean before cutting the next potato. Be sure to discard all potatoes from the sample sets that have come into contact with the test strips.

Sources:

Maintenance of Potato Processing Quality by Chemical Maturity Monitoring (CMM); http://conservancy.umn.edu/bitstream/handle/11299/123027/SB586.pdf?sequence=1

Potato Grower; http://conservancy.umn.edu/bitstream/handle/11299/123027/SB586.pdf?sequence=1

Leave A Comment