Sushi is best made with rice slightly warmer than room temperature, so it’s not uncommon to see sushi rice held in the “danger zone” for several hours. Health departments have been cracking down on testing the pH of sushi rice, and although the guidelines vary by state, most municipalities have similar regulations and testing methods.

Sushi Rice Preparation

Sushi rice contains vinegar, which is very acidic, so it does inhibit microbial growth. Most health departments have a guideline that the pH of the rice must be below 4.6. However, it’s important to remember that you should always check with your local health officials to find out what regulations you must follow. In some cases, a full HACCP plan for sushi is required. In other instances, the pH is simply subject to testing by the health department.

When preparing sushi rice, bare hand contact should be minimized to prevent cross-contamination of ready-to-eat product. Heat during the cooking of rice is what can activate certain bacterial spores that can grow and release toxins, unless the rice is preserved or refrigerated. However, refrigerated rice is more difficult to form for sushi, so it’s better to carefully prepare and protect the rice during handling without refrigeration.

Proper acidification of cooked rice with vinegar helps preserve the rice for temporary handling at temperatures above 41°F. It’s best to acidify the rice when it’s warm to assure better mixing and penetration of the acid solution. The pH of the rice should be monitored for each batch.

Testing Sushi Rice pH

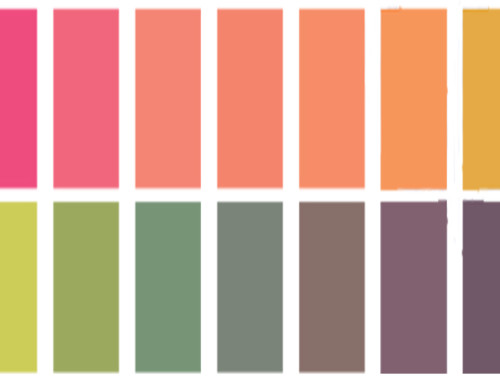

Our pH 3-6 test strips can be used to test the pH of sushi rice if approved by your health inspector. It’s a much less expensive alternative to a pH meter. The test strip measures in 0.5 pH units, so an accurate reading can be made in a narrow acidic range. To perform the test, dip the test strip into a puree of the rice. Swabbing the outside of the rice grains won’t be as accurate.

Acidified rice often has an initial measureable, targeted pH of 4.1 and should be thoroughly mixed to assure the rice doesn’t exceed a pH of 4.6.

If the pH of the rice is too high, more vinegar must be added to maintain optimum acidity. Restaurants have to take special care in making sure there’s enough vinegar to prevent potential bacterial growth, but not too much that the rice can’t be formed into balls and rolls. Properly acidified rice isn’t considered a potentially hazardous food.

Regulations vary by state, so check with your local health officials to determine the evaluation guidelines you should follow for sushi rice.

UPDATE: According to Krowne, the following steps should be taken when measuring the pH in Sushi Rice:

Measure the acidity (pH) of your Sushi Rice within 30 minutes of acidification (mixing the cooked rice and vinegar solution).

- Make a rice slurry by gathering a ¼ cup sample of the cooked, acidified rice taken from various locations in the batch and add ¾ cup of distilled water in a clear plastic or metal blend cup.

- Blend the slurry (mixture) for approximately 20 seconds to create a thorough mix.

- Remove one strip of 3060 pH test paper and hold between index finger and thumb.

- Dip the test strip into the liquid portion of the slurry for 1-2 seconds.

- Shake off excess liquid and match color of pad to color chart provided with test strips.

- Sushi Rice with an initial pH greater than 4.6 should be re-acidified with more vinegar solution and rechecked to assure a targeted pH of 4.1.

- Record the pH measurements in a pH log.

(Courtesy of Krowne)

What pH is considered to low?

Great question, Charlene. Krowne Metal Corporation suggests a targeted pH of 4.1. Check out their instructional sheet here: https://krowne.com/media/downloads/233/Krowne%20Test%20Strips.pdf. They don’t specify a pH that is too low, however, at some point, a pH that is too low will affect the taste. It may start to taste too much like vinegar. Krowne is an expert this field, so we suggest contacting them to see if they have some additional suggestions for you. Their phone number can be found at the bottom of the page on the link mentioned above (800-631-0442).

Does the rice pH increase again over time or will it stay the same once acidified?

Tracey, thank you for your question. Once acidified, it should remain stable for an extended time. Vinegar doesn’t weaken over time. Here is a link to Maricopa County regulations that state pH must be below 4.2 if the rice is to be left over time. In any case, 7 days is the time max in this regulation. https://www.maricopa.gov/DocumentCenter/View/30869/Acidified-Sushi-Rice-PDF

As said sushi rice ph above 4.6 is considered to be dangerous. Why? And why the regular cooked rice which has ph level of 6 and above is edible.?

pH test strips are primarily used for testing and recording the acid level in sushi rice. Special care needs to be taken in preparation of the rice used with sushi to prevent potential bacterial growth while assuring the rice can still be formed into balls and rolls. Proper acidification of cooked rice with vinegar recipes helps preserve the rice for temporary handling at temperatures above 41°F, but the acid level, measured by pH, should be carefully monitored for each batch. Sushi rice is acidfied to inhibit microbial growth.